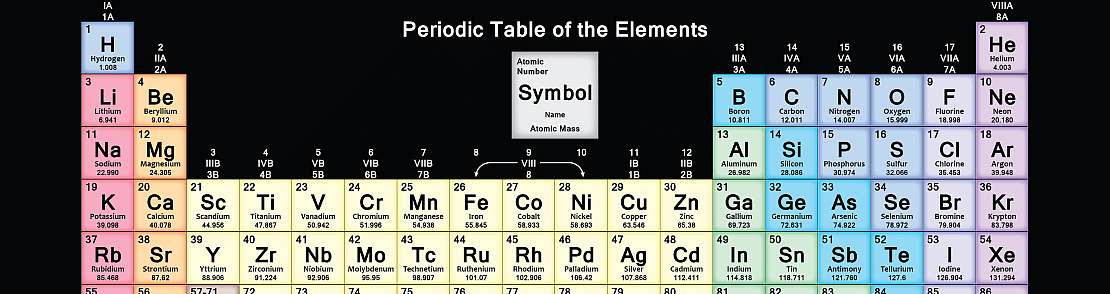

Steel comes in many different forms and grades. Industries will typically use groups of grades specific for their needs. Common grades of metals used across a range of industries are the structural steel grades such as S355J2+N and S275J0. But what do these numbers and letters mean? To answer this we first need to see the full material grade designation:

BS EN 10025-2 S355J2+N

We will go through each highlighted section in turn:

BS EN 10025-2 = This is the document which contains and specifies the material grade

S = This denotes that the material is a structural steel

355 = An indication of the specified minimum yield strength as measured by a tensile test

J2 = Denotes the quality level of this grade of material and indicates it’s impact properties

+N = Is the final treatment condition of the material